China wholesale Seamless Tube - JIS Aisi ASTM GB DIN EN China Hotsale Cold Rolled Seamless Steel Pipe – Bangrun

China wholesale Seamless Tube - JIS Aisi ASTM GB DIN EN China Hotsale Cold Rolled Seamless Steel Pipe – Bangrun Detail:

Product Description

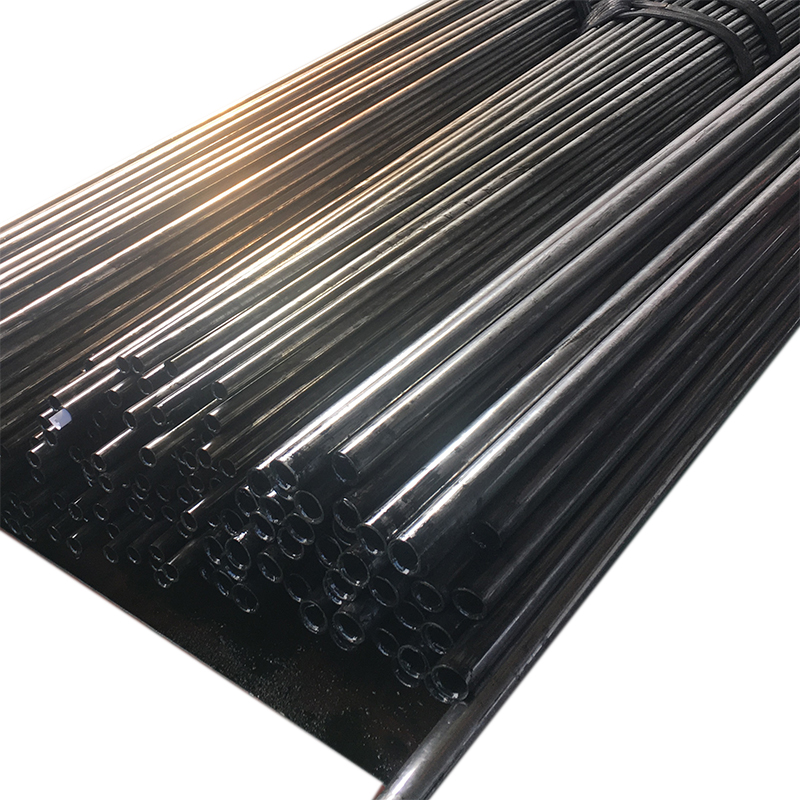

Seamless steel pipes are pipelines with a hollow section and are used in large quantities for conveying fluids, such as pipelines for conveying oil, natural gas, gas, water and certain solid materials. Compared with solid steel such as round steel, steel pipe has a lighter weight when the bending and torsion strength is the same. It is a kind of economical cross-section steel and is widely used in pipeline engineering.

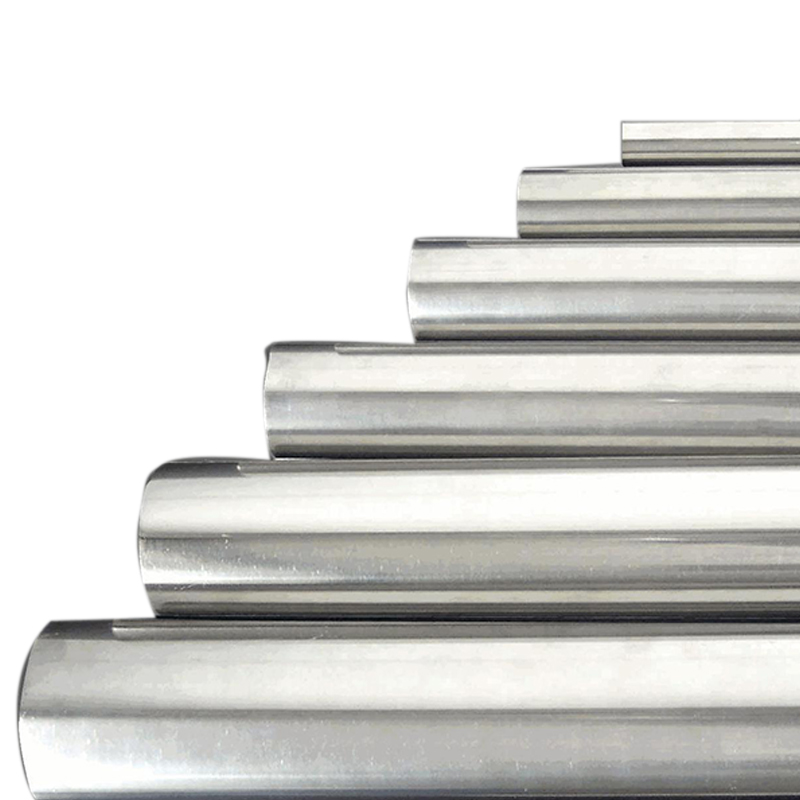

The production process of general seamless steel pipes can be divided into two types: cold-rolled and hot-rolled. In appearance, cold-rolled seamless steel pipes are shorter than hot-rolled seamless steel pipes. The wall thickness of cold-rolled seamless steel pipes is generally higher than that of hot-rolled seamless steel pipes. To be small. But the surface looks brighter than thick-walled seamless steel pipes. There is not much roughness on the surface, and there are not too many burrs on the caliber.

Application

1. Seamless pipe for structure (GB/T8162-1999) is a seamless pipe for general structure and mechanical structure.

2. Seamless pipe for fluid transportation (GB/T8163-1999) is a general seamless pipe used to transport water, oil, gas and other fluids.

3. Seamless pipes for low and medium pressure boilers (GB3087-1999) are used to manufacture superheated steam pipes, boiling water pipes for low and medium pressure boilers of various structures and superheated steam pipes for locomotive boilers, large smoke pipes, small smoke pipes and arch bricks High-quality carbon structural steel hot-rolled and cold-drawn (rolled) seamless pipes for pipes.

4. Seamless pipes for high-pressure boilers (GB5310-1995) are high-quality carbon steel, alloy steel and stainless heat-resistant steel seamless pipes for the heating surface of water-tube boilers with high pressure and above.

5. High-pressure seamless pipes for fertilizer equipment (GB6479-2000) are high-quality carbon structural steel and alloy steel seamless pipes suitable for chemical equipment and pipelines with a working temperature of -40 to 400 ℃ and a working pressure of 10 to 30 Ma.

Size Selection

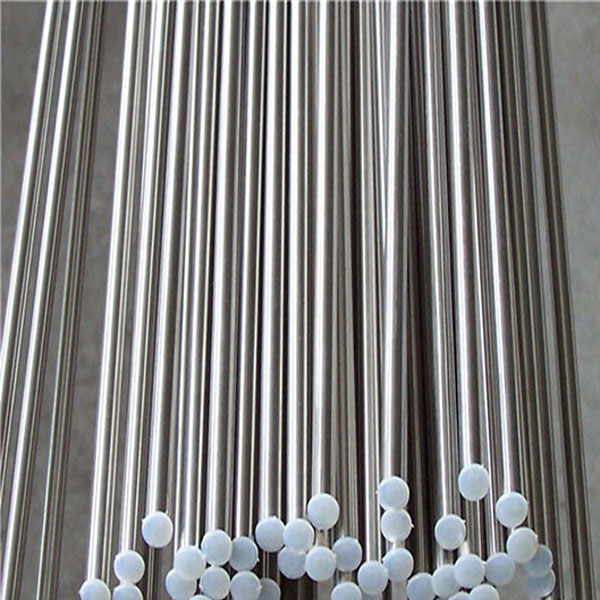

The grade of this stainless steel pipe is 316L.

|

Product name

|

Cold rolled seamless 316L stainless polished steel round tube/pipe |

|

Grade |

316l |

|

Standard |

JIS, AiSi, ASTM, GB, DIN, EN |

|

Length |

Customer Required |

|

Thickness |

1 inch etc |

|

Place of Origin |

Liaocheng ,China |

|

Brand Name |

BANGRYUN |

|

Outer diameter |

Customer Required |

|

Type |

Round tube/pipe |

|

Application |

Construction,Kitchen,Industry etc |

|

Certification |

Certification |

|

Tolerance |

±1% |

|

Item |

value |

|

Technique |

Cold Rolled |

|

Color |

silver |

|

MOQ |

1000kg |

|

Size |

Customer Required |

|

Port |

Qingdao |

Note: we provide customize service, all the steel tube will according your design to produce it.

Reasons For Choosing Bangrun Steel

Transportation

Product detail pictures:

Related Product Guide:

Our target is to consolidate and improve the quality and service of existing products, meanwhile constantly develop new products to meet different customers' demands for China wholesale Seamless Tube - JIS Aisi ASTM GB DIN EN China Hotsale Cold Rolled Seamless Steel Pipe – Bangrun , The product will supply to all over the world, such as: Islamabad, Italy, Brisbane, Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.