Factory making Carbon Steel Wearing Plate - Chinese Manufacturer Weather-resistant Structural Steel Plate for Building Decoration – Bangrun

Factory making Carbon Steel Wearing Plate - Chinese Manufacturer Weather-resistant Structural Steel Plate for Building Decoration – Bangrun Detail:

Product Description

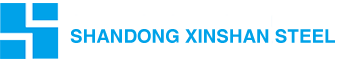

(1)A high weathering steel

High weather resistance structural steel is to add a small amount of copper, phosphorus, chromium, and nickel to the steel to form a protective layer on the surface of the metal collective to improve the performance of the steel against atmospheric corrosion. You can also add a small amount of molybdenum, niobium, Elements such as vanadium, titanium and zirconium can refine the grains, improve the mechanical properties of steel, improve the strength and toughness of steel, reduce the brittle transition temperature, and make it have better resistance to brittle fracture.

(2)Weathering steel for welded structure

The elements added to the steel, except for phosphorus, are basically the same as high weather resistance structural steel, and have the same function as it, and improve the welding performance.

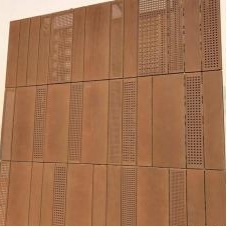

Application

The use of high weather resistance structural steel is better than weather resistance steel for welded structure because of its atmospheric corrosion resistance. It is mainly used for bolting, riveting and welding structural parts for vehicles, containers, buildings, towers and other structures. When used as welded structural parts, the thickness of the steel should not be greater than 16mm. Weather-resistant steel for welded structures has better welding performance than high-weather-resistant structural steel, and is mainly used for welded structural parts for bridges, buildings and other structures.

Note: we provide customize service, all the steel tube will according your design to produce it.

Parameter

| Weather resistance level and performance index | ||||||||||||||

| Steel Grade | Standard | Yield Strength N/mm2 | Tensile Strength N/mm2 | Elongation % | ||||||||||

| Corten A | ASTM | ≥345 | ≥480 | ≥22 | ||||||||||

| Corten B | ≥345 | ≥480 | ≥22 | |||||||||||

| A588 GR.A | ≥345 | ≥485 | ≥21 | |||||||||||

| A588 GR.B | ≥345 | ≥485 | ≥21 | |||||||||||

| A242 | ≥345 | ≥480 | ≥21 | |||||||||||

| S355J0W | EN | ≥355 | 490-630 | ≥27 | ||||||||||

| S355J0WP | ≥355 | 490-630 | ≥27 | |||||||||||

| S355J2W | ≥355 | 490-630 | ≥27 | |||||||||||

| S355J2WP | ≥355 | 490-630 | ≥27 | |||||||||||

| SPA-H | JIS | ≥355 | ≥490 | ≥21 | ||||||||||

| SPA-C | ≥355 | ≥490 | ≥21 | |||||||||||

| SMA400AW | ≥355 | ≥490 | ≥21 | |||||||||||

| 09CuPCrNi-A | GB | ≥345 | 490-630 | ≥22 | ||||||||||

| B480GNQR | ≥355 | ≥490 | ≥21 | |||||||||||

| Q355NH | ≥355 | ≥490 | ≥21 | |||||||||||

| Q355GNH | ≥355 | ≥490 | ≥21 | |||||||||||

| Q460NH | ≥355 | ≥490 | ≥21 | |||||||||||

| Corten | C% | Si% | Mn% | P% | S% | Ni% | Cr% | Cu% | ||||||

| ≤0.12 | 0.30-0.75 | 0.20-0.50 | 0.07-0.15 | ≤0.030 | ≤0.65 | 0.50-1.25 | 0.25-0.55 | |||||||

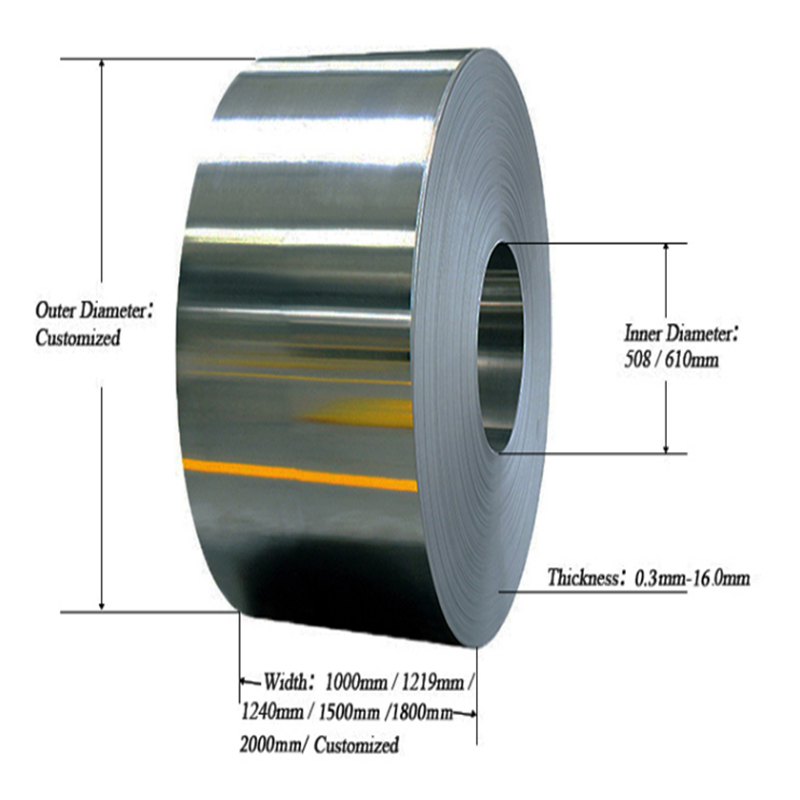

| Size | ||||||||||||||

| Thickness | 0.3mm-2mm(cold rolled) | |||||||||||||

| Width | 2mm-50mm(hot rolled) | |||||||||||||

| Length | Coil or as you need length | |||||||||||||

| Common size | Coil:4/6/8/12*1500/1250/1800*Length(customized) | |||||||||||||

| Plate:16/18/20/40*2200*10000/12000 | ||||||||||||||

Product detail pictures:

Related Product Guide:

Our business has been focusing on brand strategy. Customers' pleasure is our best advertising. We also offer OEM company for Factory making Carbon Steel Wearing Plate - Chinese Manufacturer Weather-resistant Structural Steel Plate for Building Decoration – Bangrun , The product will supply to all over the world, such as: Belgium, Sierra Leone, Bangladesh, After years of development, we have formed strong ability in new product development and strict quality control system to ensure excellent quality and service. With the support of many long term cooperated customers, our products are welcomed all over the world.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.