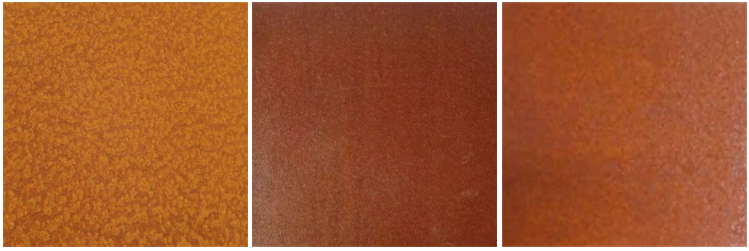

Weathering steel plate:

Weathering structural steel is atmospheric corrosion-resistant steel, which belongs to low-alloy high-strength structural steel. According to its main characteristics, it is divided into high weathering structural steel and weathering steel for welded structures.

Classification:

A high weathering steel

High weather resistance structural steel is to add a small amount of copper, phosphorus, chromium and nickel elements to the steel to form a protective layer on the surface of the metal collective to improve the atmospheric corrosion resistance of the steel, and a small amount of molybdenum, niobium, Vanadium, titanium, zirconium and other elements are used to refine the grains, improve the mechanical properties of the steel, improve the strength and toughness of the steel, reduce the brittle transition temperature, and make it have better resistance to brittle fracture.

Weathering steel for two welded structures

The elements added to the steel, except for phosphorus, are basically the same as those of the high weather resistance structural steel, and their functions are also the same, and improve the welding performance.

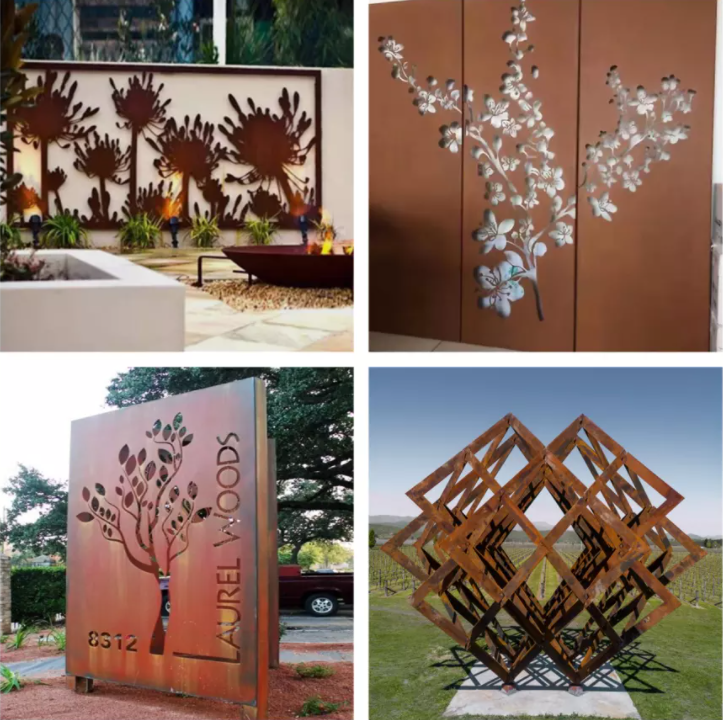

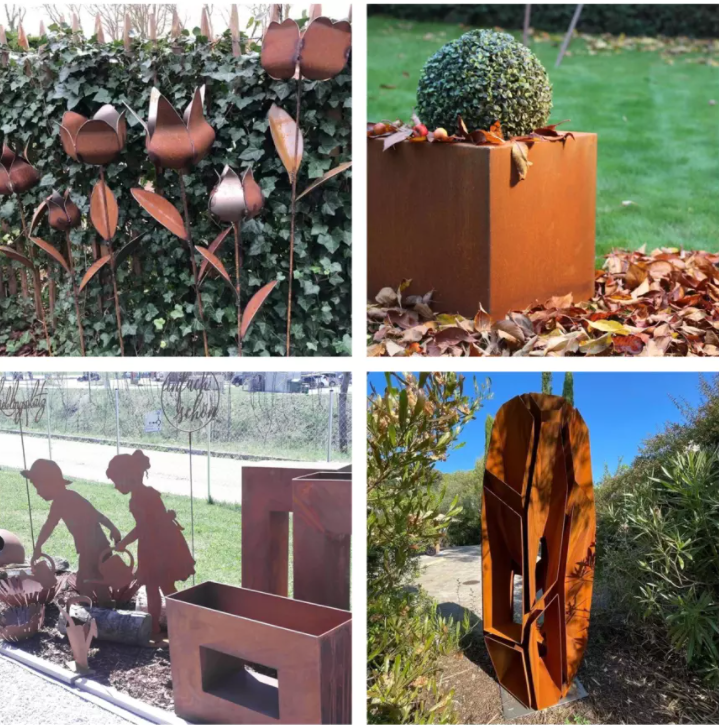

use:

The use of high weathering structural steel is mainly used for bolted, riveted and welded structural parts for vehicles, containers, buildings, towers and other structures due to its better atmospheric corrosion resistance than weathering steel for welded structures. When used as welded structural parts, the thickness of the steel should be no more than 16mm. The welding performance of weathering steel for welded structure is better than that of high weathering structural steel, and it is mainly used for welded structural parts of bridges, buildings and other structures.

Post time: Jul-28-2022